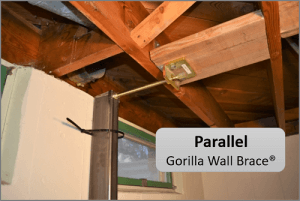

PARALLEL Gorilla Brace

$129.95

PARALLEL Gorilla Wall Brace

Includes the floor bracket, brace assembly, support brackets and all the nuts, bolts screws, washers needed for installation.

** REQUIRED STEEL BEAM IS NOT INCLUDED **

In addition, 5-6 pieces of wood blocking are needed to install each parallel Gorilla Wall Brace®. NOTE: You also need a torque wrench to tighten your Gorilla Wall Braces®.

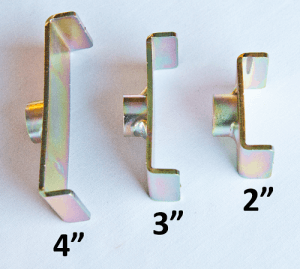

Choose the size of the Pushing Rod Idler based on the width of your steel beam before adding to the cart (no price difference).

• Select the 4″ Idler if using the H-beam

• Select the 3″ Idler if using the I beam

• Select the 2″ Idler if using a 2″x4″ tube steel

NOTE: Each Pushing Rod Idler is designed to fit the recommended steel beam like a glove – so the 2″, 3″ or 4″ are not exact measurements as they are sized to each beam.

Description

PARALLEL Gorilla Wall Braces Kit

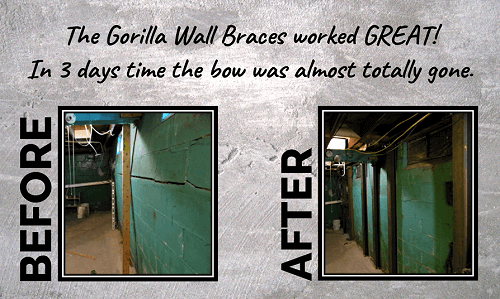

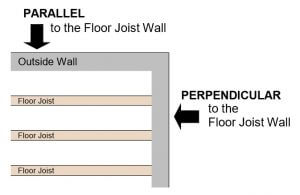

PARALLEL Gorilla Wall Braces are used to straighten bulging basement walls that are PARALLEL to the ceiling floor joists.

PARALLEL Gorilla Wall Braces are used to straighten bulging basement walls that are PARALLEL to the ceiling floor joists.

Each Gorilla Wall Brace comes as a kit that includes the floor bracket, brace assembly, support brackets and all the nuts, bolts screws, washers needed for installation. The required wood blocking and steel beam are NOT included.

** REQUIRED STEEL BEAM IS NOT INCLUDED **

Per our engineering testing specifications, Gorilla Wall Braces® need to be installed every 32 inches or 48 inches along the bowing/bulging basement wall that you wish to straighten depending on the wall type (see specifications below).

An engineered floor bracket is included in each kit. The bracket requires no removal of the concrete floor. NOTE: if the floor is too thin or deteriorated for the screw anchors to hold, cut out a 16″x16″ square in the basement floor where the brace would be located and pour a new concrete pad reinforced with rebar into existing concrete. 4″ depth (or greater) is required.

An engineered floor bracket is included in each kit. The bracket requires no removal of the concrete floor. NOTE: if the floor is too thin or deteriorated for the screw anchors to hold, cut out a 16″x16″ square in the basement floor where the brace would be located and pour a new concrete pad reinforced with rebar into existing concrete. 4″ depth (or greater) is required.

Written installation instructions are included in each order, along with a link to a 12 minute online video to guide homeowners through the entire installation process. Instructions and video are copyrighted materials and only available after purchase of Gorilla Wall Braces®.

STEEL BEAM SPECIFICATIONS…

The steel beams are NOT included with Gorilla Wall Braces®. To find them locally, do a google search for “steel ibeams near (where you live)”. Or, you can purchase them online at: MetalsDepot.com (a 10% off coupon is emailed after you purchase Gorilla Wall Braces®).

Requirements for basement walls under 8′ high (and soil level under 7′) – 3 options:

- steel H-beam, 13 lbs per foot – W 4 x 13 lb (4.16″ x .280″ x 4.06″) A572/A992 Steel (choose 4″ idler)

- steel I beam, 9.5 lbs per foot – S 4 x 9.5 lb (4.00″ x .326″ x 2.796″) A36/A572-50 Standard Steel (choose 3″ idler)

- 2″ x 4″ tube steel at 1/4″ thickness (2” side goes against wall to ensure proper yield strength — choose 2″ idler)

Requirements for basement walls 8′ or higher (and soil level higher than 7′) – 2 options:

- steel H-beam, 13 lbs per foot – W 4 x 13 lb (4.16″ x .280″ x 4.06″) A572/A992 Steel (choose 4″ idler)

- 2″ x 4″ tube steel at 5/16″ thickness (2” side goes against wall to ensure proper yield strength — choose 2″ idler)

We recommend I-beams/H-beams on block walls since they have more surface area and will more efficiently spread out the pressure against the wall, but 2″x4″ steel beams are an acceptable option in accordance with our engineering specifications.

Rod Idler Sizes to center Pushing Rod on steel beam (see requirements above):

BRACE SPACING SPECIFICATIONS…

Spacing requirements for Gorilla Wall Braces® based on our engineering specifications…

- 32″ spacing for 8″ block walls

- 48″ spacing for 10″ or 12″ block and poured basement walls (use closer spacing if basement wall is cracked in different directions)

If your basement wall has these conditions…

- cracked/crumbling blocks

- wall shear (the basement wall is shifted off a course of blocks – typically the bottom course)

- vertical cracking (not applicable to stair-step cracking in corners)

- tipping in from the top

- basement ceiling floor joists are soft/rotten

Please CONTACT US to find one of our professional contractors near you for repair options.

How to Measure Beam Locations…

PARALLEL

Measure from the basement floor to the bottom of the basement ceiling floor joist. The steel beams can be cut longer – but not shorter.

PERPENDICULAR

This is a precise measurement. Be sure to measure each brace location individually just in case there are irregularities in your concrete floor. Measure from the bottom of the floor joist to the floor and subtract 5/8″. That 5/8″ subtraction will accommodate the 3/8″ floor bracket your steel beam will sit on and give you 1/4″ clearance on top.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| 2", 3", or 4" Pushing Rod Idler (choose width to match steel I-beam) | 2", 3", 4" |